.

|

« Back 31.01.2018 11:12 CONE-COMPOSITE sleeves repair provides for: Repair using CONE-COMPOSITE sleeves is classified as an overhaul repair method of pipelines.

Principle of operationClearances, including a clearance between the pipeline and the composite sleeve, are made leak proof by means of a pressing force created when the cone shell ring is pulled on the sleeve which is also conical. High-strength characteristics of the material of the composite sleeve and polymerizable bonding paste used during the assembly of the CCS, ensure that the load from the defective area of the pipe is completely transferred to the composite shell ring which provides for the restoration of its bearing capacity up to the level of a defect-free pipe and boosts the operating reliability of the pipeline in general. Repair using CONE-COMPOSITE sleeves is classified as an overhaul repair method of pipelines.

The CONE-COMPOSITE sleeves has two modifications: Cone-Composite and Cone-Composite Plus

Intended use of the CONE-COMPOSITE sleeves

|

|

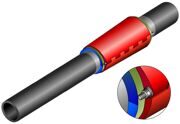

The sleeve 2 is made from a composite material which is good in compression and ensures that the radial load from the defect area is transferred to the shell ring which is also made from a composite material which is bad in expanding and has an elasticity modulus of at least 130 hPa, with this value being as near as possible to the elasticity modulus of pipe steels, but for composites.

The external surface of the composite sleeve 2, as well as the external and internal surfaces of the shell ring 3, are all conical. The composite sleeve 2 is comprised of two components parts 2a and 2b which are interconnected during the assembly of the pipeline 1 with the defect 4.

|

The composite shell ring is comprised of two component parts 3a and 3b which are interconnected with the use of the shafts 5, with one end having a threaded part, and the other – a L-shaped fixing device. The shafts 5 pass through the loops 7 with metal bushings inside that allow bringing down clearances between the internal surface of the loops and the shafts passing through them, to a minimum, which ensures the absence of any flexural stresses and cracks inside the loops. The nuts 10 are screwed through the washers 9 on threaded parts of the shafts 5 which are passed through the loops 7 of the interconnected parts of the composite shell ring 3a and 3b. Therefore, the assembled nut 10, the washer 9 and the shaft 5 perform two functions at once: |

CONE-COMPOSITE PLUS sleeve installation

|

STEP 1 The defect area is cleaned for the CLAMP LOCK sleeve installation. |

STEP 2 Mounting the sleeve CLAMP LOCK on the pipeline. Tightening of bolted connections. Resumption of pumping.

|

|

STEP 3 Filling of the sinuses between the flanges CLAMP LOCK with the composite paste.

|

STEP 4 Degreasing the internal surfaces of both parts of the composite sleeve and applying a composite paste on them. |

|

STEP 5 Mounting the composite clutch over the Anti-swing arm and preparing the shell for assembly.

|

STEP 6 Assembling the shell next to the defective area, degreasing the outer surface of the composite sleeve and the application of composite paste on it.

|

|

STEP 7 Sliding of the composite shell along the axis of the pipe over the composite sleeve so that the L-shaped fixing of the connecting axes is caught on the edge of the composite sleeve. |

STEP 8 Tightening the nuts at the ends of the connecting axles with conventional wrenches and then using a torque wrench to the force specified in the product certificate.

|

|

STEP 9 Isolation of the repaired section of the pipeline with an overlap on the old insulation.

|

CONE-COMPOSITE sleeve delivery package

|

1 - Composite sleeve 2 - Composition shell ring 3 - Coupling shaft 4 – Washer 5 – Nut 6 - Two-component bonding paste 7 - Identification plate 8 - Data sheet 9 - Installation guide |